The reasons for choosing an urban solid waste shredding and sorting line are singular: high processing efficiency, flexible line layout, and maximizing resource value.

However, an efficient production line is not a single machine, but a collaborative system that integrates crushing, sorting (including magnetic separation, air separation, screening, and optical sorting), conveying, intelligent control, and dust and odor removal. The appropriate configuration depends on the complexity of the solid waste composition, the initial material size, the target capacity (20-200 tons/hour), the final product purity requirements, and site limitations.

This guide will analyze the core components of a solid waste shredding and sorting line, typical process schemes, key parameter decision tables, core cost factors, and delivery and commissioning cycles, and provide proven and mature solutions for municipal solid waste, bulky waste, construction waste, and waste tires.

————————————————————————————————————————————————————————————————————————————–

1) Core Module Types of Urban Solid Waste Crushing and Sorting Production Lines

1.1 Modular Fixed Sorting System

Most Suitable for:

– Large-scale solid waste treatment centers or resource recovery parks

– Projects with stable sites and planned long-term operation (5+ years)

– Extremely high requirements for processing capacity, product purity, and environmental protection (e.g., RDF preparation, high-purity recycled aggregate)

Main Advantages:

– Large and stable processing capacity, capable of designing complex sorting processes

– Easy integration with deep sorting equipment (e.g., AI optical sorting, eddy current separators)

– More comprehensive supporting environmental protection facilities (dust removal, noise reduction, wastewater treatment)

Trade-offs:

– Large initial civil engineering and installation work

– Difficult or extremely high relocation costs

1.2 Mobile/Semi-Mobile Crushing and Sorting Units

Most Suitable for:

– Solid waste treatment service providers operating in multiple locations

– Projects with short site rental periods or requiring rapid production

– On-site treatment of urban construction waste and bulky waste

Main Advantages:

– Rapid deployment, reduced material transportation costs

– Low infrastructure requirements, fast investment recovery

– High flexibility, can be migrated with the project

Trade-offs:

– Single-line processing capacity is usually lower than fixed-line

– Sorting depth and product purity may be limited by equipment integration

————————————————————————————————————————————————————————————————————————————–

2) Buyer’s actual application process flow

2.1 Mixed municipal solid waste (RDF/SRF preparation) – Fine sorting process

Bag opener→ Trommel screen (coarse separation) → Magnetic separation (iron removal) → Air separation (separation of light and heavy materials) → AI optical sorting (extraction of plastics and paper) → Fine crushing (RDF production)

Reasons:

– Pre-crushing ensures uniform subsequent sorting

– Multi-stage sorting ensures the purity and calorific value of combustible materials (RDF)

– AI sorting significantly improves the recovery rate of high-value recyclables

2.2 Construction waste – High-purity aggregate recycling process

Feeding → Coarse crushing (jaw crusher/impact crusher) → Iron removal → Screening (multi-stage) → Manual sorting table/air separation (impurity removal) → Fine crushing (optional) → Finished aggregate

Reasons:

– Iron removal protects equipment and improves aggregate quality

– Multi-stage screening yields aggregates of various specifications

– Air separation/manual sorting removes light materials such as sawdust and plastic

2.3 Waste Tires – Steel Wire and Rubber Powder Co-production Process

Tire shredding → Steel wire separation (magnetic separation) → Medium crushing → Screening → Fiber separation (air separation/vibration) → Fine grinding (rubber powder)

Reasons:

– Shredding followed by magnetic separation efficiently recovers steel wire

– Multi-stage crushing and separation ensure the purity and fineness of the rubber powder

————————————————————————————————————————————————————————————————————————————–

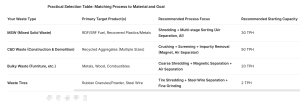

3) Practical selection table: Matching the process to the material and target

Practical Selection Table: Matching Process to Material and Goal

————————————————————————————————————————————————————————————————————————————–

4) Key parameters determining its effectiveness

4.1 Material composition and crushing difficulty

– Composition complexity: Determines the type and quantity of sorting equipment (e.g., whether a bouncing screen or eddy current separator is needed). – Material hardness and toughness: Determines the type of crusher (e.g., shear crushers are suitable for tough materials, jaw crushers/impact crushers are suitable for brittle materials).

4.2 Target Products and Economic Benefits

– If the target is high-purity recycled aggregate, screening and impurity removal (air separation, water washing) need to be strengthened.

– If the target is high-calorific-value RDF, priority should be given to ensuring the purity of combustible material separation, and the crushed particle size must meet molding requirements.

– Economic calculation: Production line costs need to be comprehensively weighed against the selling price of recycled products, waste disposal fees, and government subsidies.

4.3 Environmental Protection and Site Constraints

– Dust, noise, and wastewater treatment requirements directly affect equipment selection (enclosed design, dust removal system level).

– Site shape and area determine the production line layout (linear, L-shaped, U-shaped).

4.4 Intelligence and Control Level

– The degree of automation (PLC central control, fault self-diagnosis) affects labor costs and operational stability.

Data monitoring (output, energy consumption, equipment status) is the foundation for achieving lean operations.

————————————————————————————————————————————————————————————————————————————–

5) Typical Buyer Configurations (For Quotation Reference)

Option A — High-Value Mixed Municipal Solid Waste Sorting Line (Capacity 30-50 tons/hour)

– Plate feeder + pre-crusher

– Drum screen (sieving three grades of materials)

– Magnetic separator (iron removal)

– Air separator (separating light and heavy materials)

– AI intelligent sorting platform (sorting plastic bottles and paper)

– RDF fine crusher + molding machine

– Dust and odor removal system

Option B — Construction and renovation waste resource recovery production line (Capacity 80-150 tons/hour)

– Heavy-duty feeder + waste shredder machine

– Magnetic separator

– Double-layer vibrating screen (separating soil and fine materials)

– Impact crusher (medium crushing, shaping)

– Three-layer precision vibrating screen (producing 3-4 aggregate specifications)

– Light material air separator

– Centralized dust removal system

Option C — Mobile bulk Waste Processing Units (On-site Processing)

– Tracked Shear Crusher

– Magnetic Separator

– Compact Air Separator

– Belt Conveyor System

– Integrated Diesel Power and Simple Dust Removal

————————————————————————————————————————————————————————————————————————————–

6) Cost Drivers and Delivery Time (Buyer’s Core Concerns)

Which factors have the greatest impact on price?

1. Sorting Depth and Accuracy: Adding AI sorting, eddy current separation, and other units significantly increases cost and value.

2. Crusher Power and Durability: Processing complex solid waste requires more robust blades, spindles, and machine bodies.

3. Environmental Protection Standards: Standards for dust removal, deodorization, and soundproof enclosures.

4. Automation and Control Level: Configuration of PLC system, sensors, and monitoring software.

5. Production Line Material and Wear-Resistant Treatment: Whether components in contact with materials are made of wear-resistant steel plates or special alloys.

Typical Delivery and Commissioning Cycles

– Standard Modular Production Line: Approximately 8-16 weeks from order placement to delivery, depending on configuration complexity.

– On-site Installation and Commissioning: Assuming the foundation is ready, installation, integrated commissioning, and trial operation typically take 2-4 weeks.

– Mobile Units: Faster delivery; commissioning is usually completed within one week.

————————————————————————————————————————————————————————————————————————————–

7) Actual Application Scenarios (How to Define Your Needs)

– Municipal Solid Waste Treatment Centers: Focus on “overall processing capacity” and “resource recovery rate,” requiring long-term stable operation data and comprehensive solutions.

– Environmental Engineering Companies and Contractors: Focus on “equipment flexibility” and “investment return cycle,” emphasizing modular design, rapid installation, and applicability to multiple scenarios.

– Recycling Companies: Focus on “final product purity” and “operating costs,” requiring sorting efficiency data and details of energy consumption and wear part consumption.

————————————————————————————————————————————————————————————————————————————–

Frequently Asked Questions (FAQ)

1. What is the typical capacity range of a municipal solid waste crushing and sorting production line?

Depending on the configuration, the common range is 20-200 tons/hour. Small mobile lines are approximately 20-30 tons/hour, while large stationary integrated sorting lines can reach 150-200 tons/hour or higher.

2. How should I choose between stationary and mobile lines?

For long-term, large-scale, and in-depth processing, choose stationary lines; for short-term, multi-site, and quick-start projects, choose mobile lines.

3. Is an air separator necessary for processing construction waste?

If a low content of lightweight impurities (plastics, wood chips) in the aggregate is required, an air separator is almost essential. It is one of the key pieces of equipment for increasing product value and selling price.

4. What is AI intelligent sorting? Is it suitable for me?

AI intelligent sorting automatically identifies and sorts specific materials (such as various plastics and paper) using cameras and machine learning algorithms. It is suitable for projects that pursue high recycling value, have large processing volumes, and where manual sorting costs are high.

5. How many workers are required to operate the production line?

Highly automated production lines require only 1-2 people for monitoring in the central control room and several people for on-site inspections. Low-automation lines may require a large number of workers on the sorting platform.

6. How to ensure the production line meets environmental standards?

Systematic configuration is required: fully or semi-enclosed workshops, focused dust removal at the feed inlet and crushing point, sealed belt conveyors throughout the line, high-efficiency dust collectors (such as bag filters), and, if necessary, an odor control system.

7. What are the lifespan and replacement costs of easily worn parts (such as blades and screens)?

Lifespan depends on the abrasiveness of the material. For example, in processing municipal solid waste, the blade life of a shear crusher can reach hundreds to thousands of hours. Equipment with wear-resistant materials and easy-to-replace structures should be selected to reduce long-term costs.

8. What information do I need to provide to obtain an accurate quote?

– Detailed composition and proportions of the material to be processed

– Maximum initial size and moisture content of the material

– Target processing capacity per hour/day

– Desired final products and their purity requirements

– Site conditions (size, power supply, environmental requirements)

– Budget range and intended investment model

————————————————————————————————————————————————————————————————————————————–

— About Guoxin Machinery Guoxin Machinery focuses on providing customized integrated solutions for the crushing, sorting, and resource recovery of municipal solid waste for global clients. We not only provide equipment, but also offer full-cycle services from process design, equipment manufacturing, installation, and commissioning to operational support, helping your solid waste projects achieve higher environmental and economic benefits.