Products Description

Construction Waste Sorting Machine

Construction waste has become one of the fastest-growing waste streams worldwide. Efficient sorting is key to reducing landfill waste, increasing recycling rates, and improving project profitability.

This article explains how a construction waste sorting machine works, how much it costs, and how to choose the right solution for your project.

1. What Is a Construction Waste Sorting Machine?

A construction waste sorting machine is a complete system designed to separate mixed construction and demolition (C&D) waste into reusable materials such as:

- Concrete and aggregates

- Bricks and stones

- Wood

- Metals

- Plastics

- Light combustible materials

Instead of manual sorting, modern systems use mechanical, air, magnetic, and intelligent separation technologies to achieve higher efficiency and lower labor costs.

Our construction waste sorting machine efficiently processes mixed construction debris, such as concrete, wood, and metals, enabling easy recycling and resource recovery. By integrating advanced sorting technologies, we help minimize landfill usage and maximize material recovery.

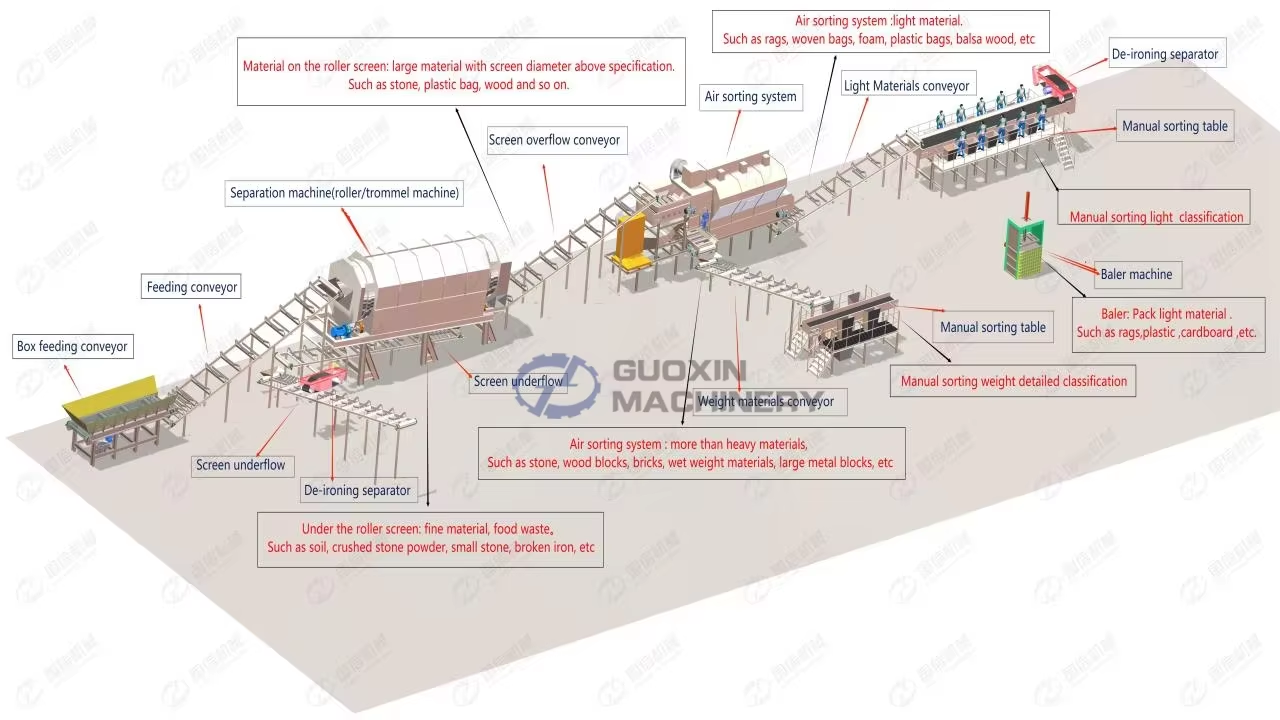

2. Typical Construction Waste Sorting Process

A standard waste sorting line usually includes the following steps:

- Feeding System – Uniform feeding of mixed waste

- Bag Opener / Pre-shredder – Loosens compacted materials

- Trommel Screen – Separates by particle size

- Air Separator – Separates light and heavy materials

- Magnetic Separator – Removes ferrous metals

- Eddy Current Separator – Separates non-ferrous metals

- Manual or Intelligent Sorting – Final quality control

The process can be flexibly adjusted according to waste composition and capacity requirements.

Plate feeder

Magnetic separator

Air separator

3. How Much Does a Construction Waste Sorting Machine Cost?

The price of a construction waste management machine depends on several key factors:

| Factor | Impact on Cost |

|---|---|

| Processing capacity (TPD) | Higher capacity = higher investment |

| Degree of automation | Manual vs semi-auto vs fully automatic |

| Waste composition | More complex waste = more equipment |

| Local labor cost | Affects the automation level |

| Turnkey scope | Design, installation, and training included |

Typical Investment Range

- Small-scale system (100–200 TPD): USD 150,000 – 300,000

- Medium-scale system (300–500 TPD): USD 300,000 – 600,000

- Large-scale fully automatic line: Customized quotation

Exact pricing requires waste analysis and capacity confirmation.

4. Manual vs Automatic Construction Waste Sorting

| Item | Manual Sorting | Automatic Sorting |

|---|---|---|

| Labor cost | High | Low |

| Sorting accuracy | Unstable | Consistent |

| Processing capacity | Limited | High |

| Long-term ROI | Low | High |

For long-term projects, automatic or semi-automatic systems provide better ROI.

5. Turnkey Construction Waste Sorting Solution

We provide complete turnkey solutions, including:

- Waste analysis & project evaluation

- Plant layout and process design

- Equipment manufacturing and supply

- Installation and commissioning

- Operator training and after-sales support

Each solution is tailored to your specific waste type, site conditions, and investment budget.

6. Which Projects Is This Solution Suitable For?

- Urban construction waste recycling centers

- Demolition waste treatment plants

- Government or PPP waste management projects

- Contractors seeking on-site or centralized sorting solutions

7. Get a Free Construction Waste Sorting Solution

If you are planning a construction waste recycling project, we can help you:

- Design the most cost-effective sorting line

- Calculate investment and operating costs

- Improve recycling rate and project profitability

Contact us now to get a free customized construction waste management solution and price estimation.

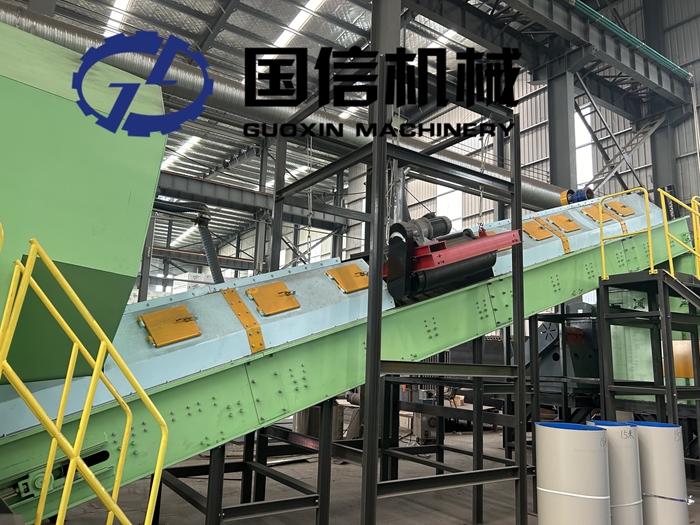

Working site of the production line

Cooperative client