Products Description

solid waste shredder production line

Introduction of Municipal Solid Waste Shredder Production Line

Two-Shaft Shredders are small to large size reduction machines suitable for processing a wide range of materials to a smaller size. The products can often be sold as is or be sent for further processing through additional equipment. Typically range between 300kg/hr – 20,000kg/hr depending on the model, material type, and application

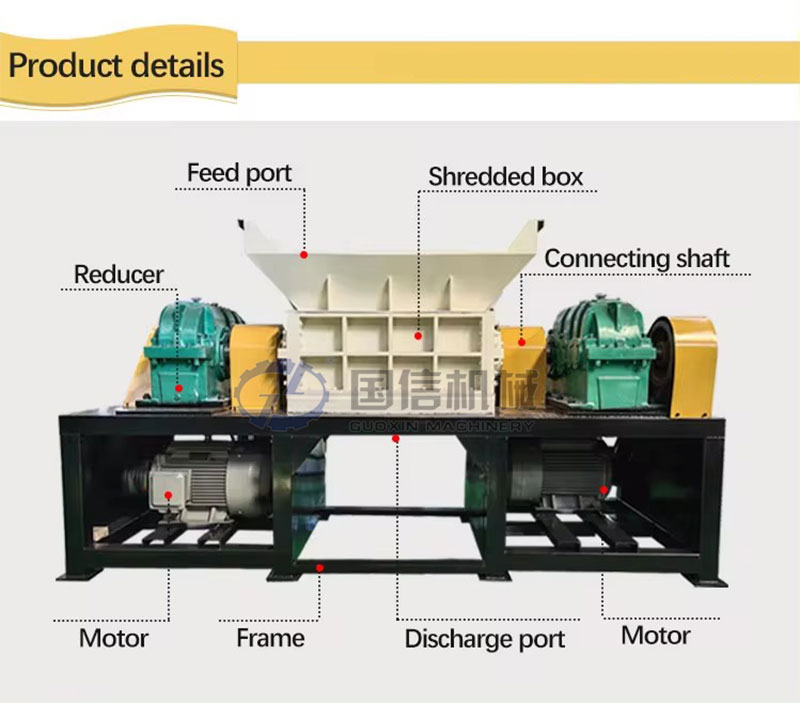

Components of the waste shredder

Reducer

The internal gear of the planetary reducer is carburized and quenched with 20CrMnTi, which has the characteristics of small volume, light weight, high bearing capacity, long service life, stable operation, low noise, large output torque, and high speed ratio.

Working Chamber

The box is processed by a high-precision CNC machining center and drilled as a whole to ensure the stable operation of the equipment under high load for a long time and prolong the service life of the transmission parts.

Blade

1. Raw material is H13. After special heat treatment, the Rockwell hardness is 58-63HRC;

2. Knife edge groove design, cushion, and reduce the resistance during shearing;

3 . Can repair and reuse under normal temperatures.

Main Shaft

High-strength alloy steel is used to improve the mechanical properties of the spindle after quenching and tempering. Surface nitriding treatment, surface hardness HRC55-58 after treatment, high spindle strength, easy to install the blade and spindle, ensuring good cooperation with the tool.

Bearing

Bearing with an adapter sleeve. It can be disassembled and reassembled according to customers’ needs, which is very convenient for customers to change blades while maintaining the bearings’ good mechanical properties.

Before and after crushing

Application :

1. Metal: aluminum can bundle, steel drum, car shell, color steel tile, bicycle, copper aluminum radiator, oil filter, scrap wires, cables, aluminum composite plastic panel, steel wire rope, gas tank, iron scrap, zip-top can, engine case, paint bucket, etc.

2. Plastic: plastic pallet, plastic drum, plastic bucket, plastic film, waste appliances shell, garbage plastic drum, IBC drum, IBC barrel, garbage bag, rubbish bag, plastic pipe, washing machine, forklift pallet, lead acid battery shell, etc.

3. Textile: scrap clothes, shoes, fishing net, woven bag, ton bag, jumbo bag, fishing net bundles, dust collector bag, industrial textile waste, etc.

4. Wood: wood mattress, wood furniture, wood pallet, scrap timber, sawdust chipboard, composite board, wooden door, forklift pallet, wood board, wood template, wooden case, wooden box, wood sofa, wood bed, etc.

5. Paper: scrap paper and cartons, including scrap books, carton board, carton box, packaging box, waste newspaper, office paper, printing paper, paperboard, etc.

6. Waste household appliances: TV, washing machine, refrigerator shell, etc.

7. Pipes: large pipes, pipe fittings, PE pipes, etc.

8. Scrap tires: car tires, truck tires, etc.

9 . All kinds of Kitchen waste, household waste, RDF derivatives, garden waste, etc.

For commingled combustible waste shredding applications, a dedicated combustible waste shredding production line is recommended.