Industry data shows that it’s not uncommon for production lines with a one-time investment of 10 million yuan to have equipment utilization rates below 50% due to technological iterations or changing demands.

Instead of pursuing a perfect one-time solution, it’s better to rethink the essence of investment: what we need is not a warehouse of stacked hardware, but an organic system that can grow with the business.

1. Modular Waste Sorting System Planning

In the solid waste treatment industry, the composition of household waste fluctuates by more than 30% seasonally, new packaging materials emerge constantly, and environmental standards are updated every 2-3 years.

More realistically, there are budget constraints.

For most companies, a one-time investment of tens of millions of yuan is neither realistic nor wise. Financial data shows that even with a fourfold increase in capacity, the total investment may triple, but the unit processing cost will significantly decrease.

2. Modular Waste Sorting System Solutions

The core of the modular Waste Sorting system design lies in the perfect combination of standardization and flexibility.

It transforms the production line from a rigid whole into a set of freely combinable Lego bricks. This design concept has been validated in numerous successful cases.

Modular sorting line components:

Pre-processing module (shredding, screening), core sorting module (optical sorting, sorting robot), post-processing module (balering, compression), and intelligent control center.

e.g., Guangdong case study solution

Core equipment, such as the 3D sorter and AI intelligent waste sorting robot, has a total power consumption of only 11kW, yet can achieve near-unmanned operation throughout the line, with each robot replacing 3 to 4 workers.

More advanced designs even extend modularity to the mobile level.

The containerized modular design enables the entire system to be quickly relocated between different sites, making it particularly suitable for waste transfer stations, temporary processing points, and other similar scenarios. This flexibility demonstrates unique value in addressing seasonal fluctuations in waste production or temporary processing needs.

3 Waste Management Phased Investment Roadmap

1. Building Core Processing Capabilities (Approximately 40% of investment)

Establish basic waste processing capabilities and validate the feasibility of the technology roadmap.

Focus investment should be concentrated on the crushing and screening module and a core sorting technology, such as AI optical sorting or magnetic separation.

For example, the waste sorting machine at Guangxi University of Science and Technology provides a streamlined yet efficient model. Its small footprint and high degree of modularity allow for rapid project initiation and validation of the technology.

2. Refined Sorting (Approximately 30% of Investment)

Once the basic processing capacity is operating stably and generating a stable cash flow, more refined sorting modules can be considered.

For example, adding sorting robot sorting units to handle complex materials, or introducing equipment such as air separators and bouncing screens to improve sorting purity.

At this stage, the advantages of modular design are fully demonstrated—new equipment can be quickly integrated into existing production lines through standard interfaces, minimizing downtime.

3. End-to-End Intelligent Processing (Approximately 30% of Investment)

When the processing scale reaches a certain level, intelligent management and data-driven optimization become key to enhancing competitiveness. Investment at this stage shifts to intelligent control systems, data twin platforms, and automated post-processing equipment.

For example, the practical experience of Lianyun Environment shows that by using an AI system to achieve high-speed identification of 5760 times per second, the material identification accuracy can be consistently maintained above 99.2%. Processing 160 tons of recyclables per day requires only 18 operators, increasing efficiency by more than 6 times compared to traditional methods.

4. Long-Term Investment Value Lock-in

The financial significance of modular design goes far beyond initial investment savings. It fundamentally changes the asset value and risk structure of solid waste management projects, giving investments the flexibility to cope with the future.

From a financial perspective, the biggest advantage of modular production lines lies in transforming long-term uncertainty into controllable, phased decisions. The biggest risks of traditional one-time investments are technological obsolescence and changing demands, while modular design, through reserved interfaces and standardized protocols, ensures that the system can be upgraded as technology advances.

When evaluating investment options, corporate executives not only focus on the initial investment size but also calculate the total cost of ownership (TCO) and the investment payback period. Research shows that intelligent sorting systems using modular design can shorten the investment payback period to 2-4 years, far shorter than the 5-7 years of traditional equipment.

Economic analysis further reveals that unit processing costs show a significant downward trend as processing scale expands. Studies show that when processing capacity increases from 25,000 tons to 100,000 tons, the cost per ton of waste can drop from €110 to €70. This means that by scaling up modularly, companies can maintain a cost advantage at every stage.

Modular design also creates financial flexibility for companies. When market conditions change or technological breakthroughs occur, companies can adjust subsequent investment plans instead of being forced to accept the sunk costs of already invested equipment. This flexibility is particularly valuable in the rapidly changing environmental industry.

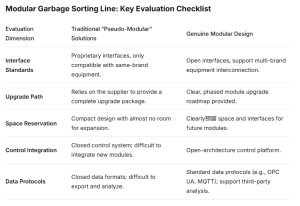

5 Your Modularity Assessment Checklist

Supplier Modular Solution Assessment:

Waste management Modular solution evaluation

Beyond technical considerations, it’s also necessary to assess the supplier’s long-term commitment from a business perspective.

Inquire whether the supplier has a clear algorithm iteration plan and software update roadmap, as future value growth will increasingly depend on continuous software upgrades.

Observing the practices of industry leaders is also enlightening. Some forward-thinking urban sanitation groups have already included support for third-party algorithms and open data interfaces as key scoring items when purchasing equipment. This approach of decoupling hardware and software effectively avoids vendor lock-in and ensures long-term freedom of technology choice.

Ultimately, victory belongs not to the companies with the most expensive equipment, but to those who best understand how to keep their investments dynamic and valuable.

Contact Eve: eve@guoxinmachinery.com for customized modular waste sorting system solutions.