Products Description

Commingled Combustible Waste Shredding Solution for RDF & Waste-to-Energy Projects

In modern waste management and waste-to-energy projects, commingled combustible waste plays a critical role as a valuable energy resource.

A commingled combustible shredder is a key piece of equipment used to process mixed combustible waste into uniform fuel suitable for RDF production or incineration systems.

This page explains how a commingled combustible shredder works, where it is used, and how to select the right solution for your project.

1. What Is Commingled Combustible Waste?

Commingled combustible waste typically includes:

- Plastics (films, rigid plastics)

- Paper and cardboard

- Textiles

- Wood

- Light packaging materials

These materials usually come from MSW sorting plants, MBT systems, or construction and demolition waste processing lines and contain high calorific value.

2. Role of Commingled Combustible Shredder in Sorting Systems

A combustible shredder is designed to:

- Reduce material size

- Create homogeneous fuel

- Improve downstream separation efficiency

- Prepare waste for RDF or waste-to-energy use

A combustible mixed waste shredder is commonly installed after air separation or manual sorting, processing light combustible fractions collected from mixed waste.

The commingled combustible shredder is a key component in the RDF production process, efficiently processing mixed waste, including plastics, paper, and textiles, into high-quality fuel. It enhances waste-to-energy systems by improving fuel consistency and increasing energy recovery.

Explore our complete [RDF Production Line Solution].

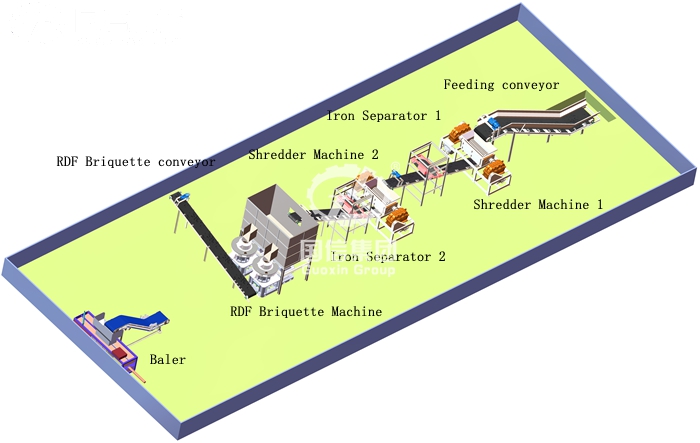

3. Typical Processing Flow

A standard commingled combustible shredding process includes:

- Feeding system (belt or hopper)

- Primary shredder (low-speed, high-torque)

- Secondary shredder (optional, for finer RDF size)

- Screening system (if required)

- Conveying and storage system

Final output size is usually 30–100 mm, depending on RDF or incineration requirements.

Combustible mixed waste shredders are essential for processing various waste types, ensuring consistent fuel quality for RDF production. Our turnkey solutions integrate shredders with energy recovery systems, enabling efficient waste-to-energy conversion.

For a complete RDF shredding solution, please refer to our dedicated RDF system.

Many buyers search for a “commingled combustible waste shredding machine” mainly to understand pricing.

In real waste-to-energy and RDF projects, shredding performance and system configuration depend heavily on waste composition, throughput capacity, and downstream fuel requirements.

For this reason, combustible waste shredding is usually designed as part of a complete RDF or waste-to-energy solution rather than a standalone machine.

4. Key Advantages of Commingled Combustible Shredder

- Stable output size for consistent fuel quality

- Low-speed, high-torque design reduces fire risk

- Wear-resistant cutters for mixed materials

- Low dust and noise level

- Suitable for high-calorie waste

These features make it ideal for continuous industrial operation.

5. Application Scenarios

A combustible shredder is widely used in:

- RDF (Refuse Derived Fuel) production lines

- Waste-to-energy incineration plants

- MBT (Mechanical Biological Treatment) systems

- MSW sorting plants with energy recovery goals

- Industrial combustible waste processing projects

6. How to Choose the Right Commingled Combustible Shredder

When selecting equipment, the following factors are critical:

| Selection Factor | Description |

|---|---|

| Waste composition | Type and proportion of combustibles |

| Required capacity | Tons per hour or per day |

| Output size | RDF or incinerator feeding standard |

| System integration | Standalone or integrated line |

| Maintenance cost | Cutter life and replacement cycle |

Proper selection ensures stable operation and long-term ROI.

7. Commingled Combustible Shredder Price Factors

The cost of a commingled combustible shredder depends on:

- Processing capacity

- Motor power and torque

- Cutter material and configuration

- Automation level

- Integration with the sorting system

Typical price ranges are project-specific and require technical evaluation.

A customized quotation is recommended for accurate budgeting.

8. Turnkey Solution for Commingled Combustible Processing

We provide complete turnkey solutions, including:

- Waste analysis and process design

- Shredder selection and customization

- Integration with MSW or RDF sorting lines

- Installation and commissioning

- Operator training and after-sales support

Each solution is designed to maximize fuel quality and system reliability.

9. Get a Free Commingled Combustible Shredding Solution

If you are planning an RDF or waste-to-energy project, we can help you:

- Design an efficient shredding system

- Optimize fuel output size and quality

- Control investment and operating costs

Contact us now to get a free commingled combustible shredder solution and technical proposal.

Combustible Waste Shredding Production Line

Commingled combustible shredder

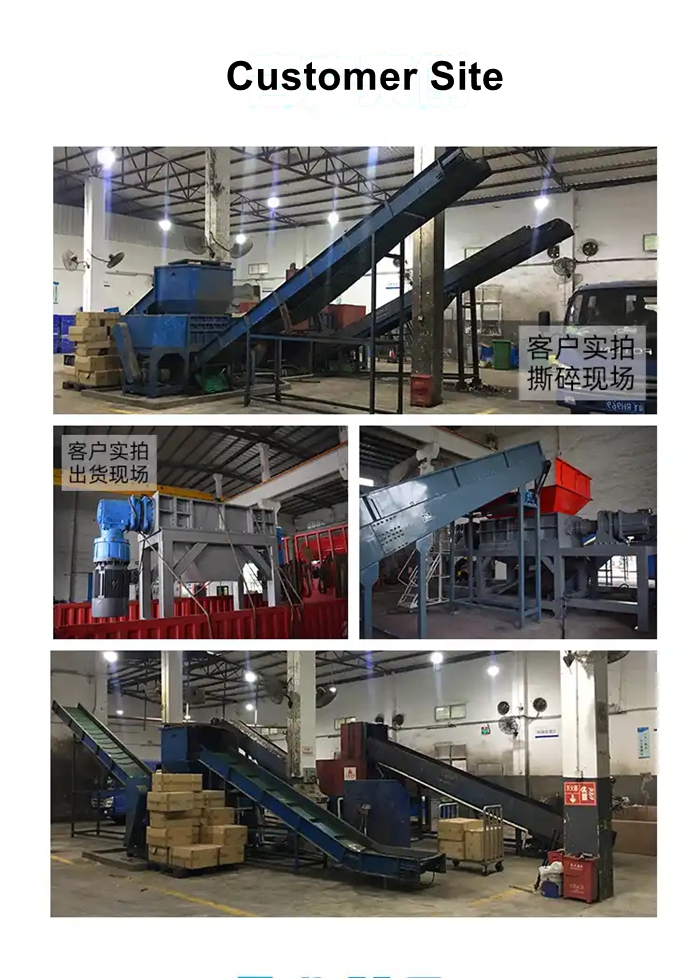

Customer’s Working Site