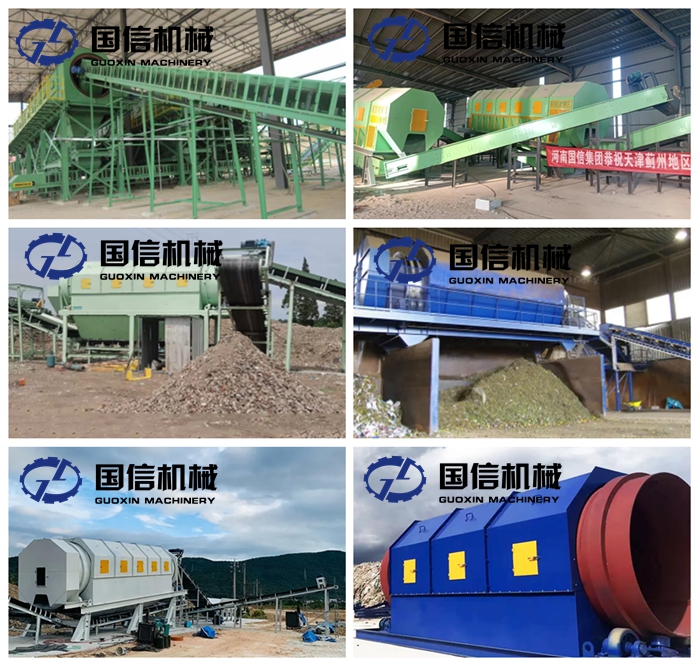

Products Description

Introduction Of Waste Trommel Screen

Trommel Screens are essential equipment in integrated waste treatment lines, suitable for screening various sizes of materials such as construction and decoration waste, municipal solid waste, silage, aged landfill waste, stone, coal, slag, and mineral slag.

The rotary trommel screen is a screening device developed by Guoxin Company for environmental engineering technology, municipal solid waste, aged waste treatment, decorative waste, and integrated waste treatment industries.

Structure and Working Principle of Waste Rotary Trommel Screens

Structure:

This machine mainly consists of a motor, reducer, drum assembly, frame, support legs, sealing protection, feed hopper, and discharge hopper. It adopts a shaftless design with rollers supporting the drum rotation, hence the name “shaftless trommel screen.”

Working Principle:

The motor drives the reducer, which in turn drives the friction wheel to rotate the drum mechanism around its axis. When material enters the drum, the rotation of the drum causes the material to rotate to a certain height, and then the material is thrown out and falls under the action of gravity. The material then proceeds belt conveyor to the next step, where it is screened by air separation to determine its weight.

Advantages:

1. Strong sorting capacity, high cost-effectiveness, strong adaptability to working conditions, convenient plate replacement, simple structure, convenient operation, high screening efficiency, suitable for screening materials of various properties, and easy to maintain.

2. The drum is made of a 16 mm steel plate, and the rotating part has a thick-walled rolling ring structure: the rotating body rotates smoothly, the conveying speed is stable, the noise is low (≤85dB), the gears mesh well, the feeding and unloading devices operate well, and there is no material leakage or falling.

3. The entire equipment is resistant to acids and alkalis, and corrosion. Key parts such as the keel are all surface-strengthened. The load-bearing wheel core is made of high-strength, high-quality structural steel and coated with polyester composite material, which is wear-resistant, pressure-resistant, and acid and alkali-resistant.

Waste Trommel Screen Certificate

Cooperative Client