Products Description

Waste Shredding Production Line

Description Of Bulky Waste Shredding Production Line

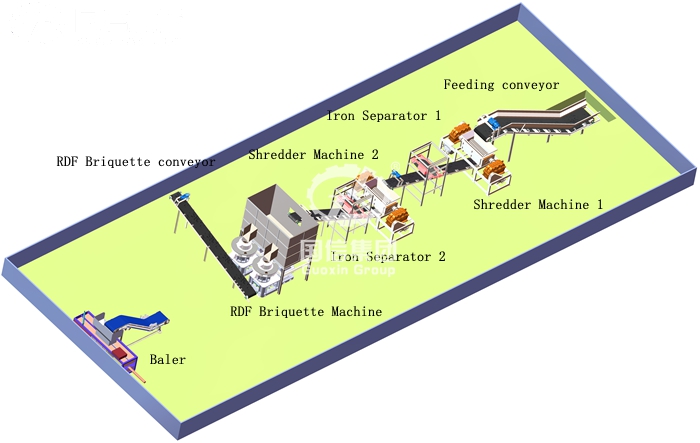

Guoxin Machinery’s design of a large garbage crushing capacity reduction program, the use of shredding + magnetic separator baler process, is designed to quickly achieve the capacity reduction of large garbage and initial resource treatment, reducing storage and transportation costs.

The material is fed into a dual-axis shredder specifically designed for handling large waste through a chain plate feeder. After the shredding process, iron metal is separated using a magnetic separator. The remaining components, such as wood, plastic, sponge, and fabric, are then compressed into bales by a baler and transported directly by a garbage transfer truck.

Waste Shredding Production Line

Advantages of Bulky Waste Shredding Production Line

11. The system provides high crushing efficiency and is suitable for a wide range of materials, which significantly reduces long-term operating costs.

2. It features a simple structure and automated operation with low overall energy consumption, helping to save on manpower, time, and operating expenses.

3. The system has a small footprint and requires a low initial investment, making it ideal for most small and medium-sized waste treatment centers.

Additionally, depending on the specific conditions of the working site, the system can be configured in three layout options: linear, L-shaped, or sunken. We can also customize a more suitable large waste disposal solution tailored to your specific needs

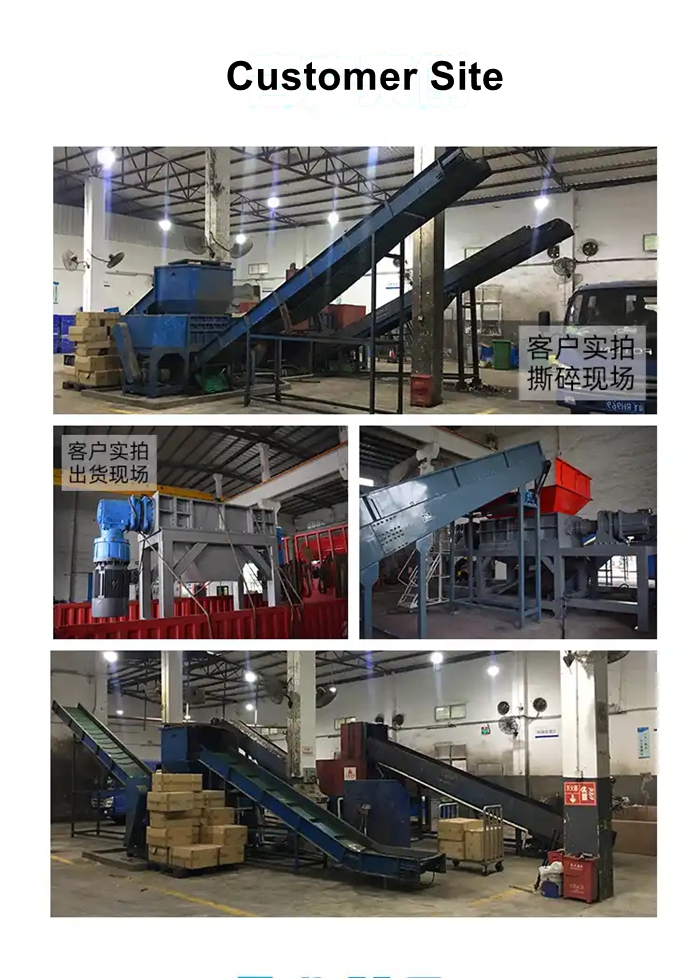

Customer’s Bulky Waste Shredding Production Line Working Site