“The vibration frequency of the bearing in the No. 3 main line drive motor is abnormal. The predicted remaining service life is 168 hours. Replacement is recommended during this week’s maintenance window.”

This isn’t science fiction; it’s a real-world application of predictive maintenance based on the Industrial Internet of Things (IIoT) and artificial intelligence.

1. The Dilemma of the Waste Sorting Industry

A typical dilemma for a logistics center manager is: after a suddenWaste Sorting equipment shutdown, the maintenance team needs hours or even longer to diagnose the fault, only to find there are no spare parts in stock, and waiting for the supplier to ship takes several more days. During this time, the entire sorting line is paralyzed, directly impacting business operations and customer satisfaction.

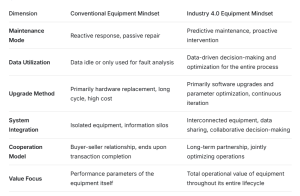

A deeper problem is that after most Waste Sorting machine suppliers complete delivery, their interaction with customers is often limited to fault reporting. The massive amounts of operational data generated by the equipment are wasted; customers cannot accumulate optimization experience from daily operations and can only passively respond to problems rather than proactively prevent them.

2. From After-Sales Service to Data Partnership

The core of this transformation is turning the equipment itself into a data source that continuously generates optimization value.

For example, in the practice of the Xuchang Tobacco Monopoly Bureau in Henan Province, they established a multi-layered collaborative operation and maintenance architecture composed of production operators, grassroots maintenance teams, provincial operation and maintenance teams, and supplier services. This architecture combines on-site experience with professional technology, significantly improving the efficiency of fault handling.

The key to this model lies in the closed-loop data flow: Equipment operation data is collected and analyzed in real time, transforming it into actionable maintenance decisions; maintenance results are fed back to the database to optimize the next predictive model.

Waste Sorting Machine is no longer a static asset, but a continuously evolving production partner.

3. From Post-Fault Repair to Predictive Maintenance

The traditional “fault-response” model is being replaced by predictive maintenance technology.

Through vibration signal analysis, temperature monitoring, and performance trend tracking, the system can identify potential problems before a fault occurs.

A study on waste sorting machine and baler machine showed that a fault diagnosis system using variational mode decomposition and an improved deep belief network model achieved an accuracy rate of 98.17%. This means that the vast majority of faults can be identified and addressed before causing downtime.

In practical applications, this technology reduces unplanned downtime by more than 70%.

More importantly, it allows maintenance activities to be scheduled during periods of low business load, minimizing disruption to operations. Simultaneously, through accurate component lifespan prediction, it optimizes spare parts inventory and reduces capital tied up in inventory.

4. Spare Parts System: From Passive Waiting to Instant Response

Reliable spare parts support is the material foundation for the long-term stable operation of equipment. Advanced suppliers have established intelligent spare parts management systems based on data analysis.

This assurance capability is underpinned by prediction based on equipment operating data: the system analyzes the average interval between failures (ATM) of similar components, combined with the specific equipment’s workload and environmental conditions, to proactively deploy potentially needed spare parts at regional service centers, achieving “predictive warehousing.”

5. Continuous Optimization of Sorting Efficiency

The training system in the Liaoning tobacco industry places particular emphasis on the technical module of equipment upgrade and retrofit selection strategies. This indicates that leading users have realized that equipment procurement is not a one-time event but should be continuously optimized based on operational data feedback.

Further practical application is reflected in the application of AI technology. For example, the intelligent sorting system of Lianyun Environment uses near-infrared and visible light fusion recognition technology to perform high-speed identification of recyclables at 5760 times per second, with a material identification accuracy rate of over 99.2%.

6. Sorting System Ecosystem Construction

The competition among sorting centers in the future will not be about individual equipment, but about the collaborative efficiency of the entire system. In a sorting center under the Industry 4.0 concept, all machines can communicate with each other, forming an intelligent network.

The direct value brought by this system-level intelligence is flexible production capacity. When demand changes or unexpected situations occur, the system can autonomously adjust production activities and consider alternative routes, requiring human intervention only when uncertain. This makes customized and small-batch production more economical.

7. Implementation Roadmap to Industry 4.0 Sorting Centers

For customers planning to upgrade their sorting capabilities, a phased implementation strategy is recommended:

Phase 1: Data Infrastructure Construction.

Add sensors to existing equipment, establish a data acquisition and monitoring system, and achieve transparent management of equipment operating status. This first stage can draw on the experience of the Liaoning tobacco industry to establish a multi-tiered operation and maintenance team and enhance data awareness and analytical capabilities.

The second stage: Introduction of predictive capabilities. Based on data accumulation, predictive maintenance algorithms will be introduced, gradually shifting from periodic maintenance to condition-based maintenance. Fault diagnosis methods with a 98.17% accuracy rate in academic research can be referenced, but optimization and adjustments need to be made according to the characteristics of the specific equipment.

The third stage: System integration optimization.

Communication protocols will be established between the equipment to achieve collaborative scheduling and optimization. At this stage, special attention should be paid to system openness to avoid vendor lock-in and to reserve space for future expansion and upgrades.

The fourth stage: Expanding ecosystem value.

The sorting system will be integrated with upstream and downstream business systems, such as order management, warehouse scheduling, and transportation planning, maximizing the scope of data value circulation. The “point-station-field” three-tier recycling network system built in intermodal transport environments can be referenced to place the sorting center within a broader operational ecosystem.

The efficient and stable operation of the line no longer depends solely on the steel hardware, but also on the intangible yet crucial data, algorithms, and forward-looking service commitments.

Become our distributor/retailer: Eve@guoxinmachinery.com