When choosing waste sorting machines, customers often struggle with comparing the pros and cons of rotary trommel screens and vibrating screens, or the technical parameters of photoelectric sorting and AI recognition, fearing they might choose the wrong equipment from a complex array of models. However, more insidious and costly pitfalls than incorrect selection often lie hidden in the equipment procurement process and documentation.

A poorly written procurement requirement may render all bids unsuitable for your actual needs;

Avague acceptance standard may force you to pay full price for substandard equipment.

To prevent failed collaborations and investment losses due to procedural oversights, we have compiled the following common “pitfalls”:

1. Waste Sorting Machine Procurement Starting Point: “Pitfalls” in Requirements Formulation

Successful procurement begins with a clear, reasonable, and legal requirements document.

Vague and general requirements are the most common problem.

For example, simply stating “a household waste sorting line is needed” without specifying the daily processing capacity, the main components of the waste, specific site limitations, and the standards for the final recycled products. This leads to huge differences in supplier quotes and a wide variety of solutions, making effective comparison impossible.

More serious is the setting of “unique” or exclusive parameters.

There have been cases where technical parameters in a project’s tender documents were deemed uniquely targeted; upon investigation, only one supplier nationwide could fully comply, leading to complaints and suspicions of “pre-selection,” ultimately resulting in the project being ordered to modify.

Another common mistake is imposing unreasonable or impractical proof requirements.

For example, forcing suppliers to provide testing reports for all raw materials when unnecessary.

According to the “Government Procurement Demand Management Measures,” the testing reports required by the procuring entity should be appropriate to the specific characteristics and actual needs of the procurement project. Excessive requirements not only increase the burden on suppliers but may also constitute unreasonable barriers.

2. Tender Evaluation: The “Word Game” of Supplier Responses

After receiving the tender documents, the evaluation stage is a crucial review of the supplier’s comprehensive capabilities and is also the stage most prone to misunderstandings and disputes.

The core is distinguishing between “substantial deviation” and “clarification of typographical errors.”

In a real-world case, the winning supplier incorrectly filled in the wrong models for both gasoline-powered and new energy vehicles in their “Itemized Quotation Sheet,” even though other technical documents proved their ability to supply qualified products.

The finance department ruled that this constituted “inconsistency in the description of similar issues,” which could be corrected through a clarification process, rather than being grounds for outright rejection. This reminds procuring entities that the review should focus on whether the supplier possesses the substantive ability to fulfill the contract, rather than dwelling on non-critical textual omissions.

Furthermore, be wary of suppliers’ ambiguous handling of “negative deviations” from key parameters.

For example, a promise of “equipment noise ≤80dB” might not be stated in the deviation table, while the industry standard or your actual requirement might be ≤75dB. This necessitates a thorough verification of the technical response sheet against the original requirements during the review process.

3. Contract Signing: From Paper Commitments to Legal Protection

The contract is a crucial step in solidifying all technical commitments and commercial terms into legal documents; oversights here can render all previous efforts futile.

Performance evaluation and acceptance clauses are of paramount importance.

The contract must clearly define the equipment’s performance indicators (such as sorting purity, throughput, and energy consumption), assessment methods, continuous and stable operation time requirements, and penalties for non-compliance.

For example, it shouldn’t just stipulate “high sorting efficiency,” but should specify “sorting purity of no less than 95% for PET plastics with a particle size ≥10mm.”

Payment milestones must be closely linked to equipment delivery, installation, and commissioning, performance evaluation, and the warranty period.

Avoid situations where the majority of the payment is made before the equipment has passed acceptance testing. A reasonable payment schedule is the most important performance lever for the purchaser.

Furthermore, spare parts and technical service agreements should be attached to the contract.

Clearly define the price, supply guarantee period, and remote technical support response time for key consumable parts (such as screens and special filter elements).

A supplier who cannot guarantee spare parts supply will expose your production line to significant downtime risks.

4. Technical Negotiation: Seeing Through the Parameters to the Essence

Technical negotiations with potential suppliers are the best opportunity to see through brochures and understand the true nature of the equipment. The following points should be emphasized:

Request experimental reports based on actual materials.

Have the supplier conduct pilot or intermediate-scale tests using representative waste samples you provide (e.g., from your city or region).

Witnessing firsthand the actual sorting performance of their equipment for your specific waste components (especially high-grease, high-moisture debris) is more reliable than any impressive specifications.

Investigate the total lifecycle cost.

Instead of comparing unit prices, jointly calculate the total cost of ownership over five years. This includes initial investment, energy consumption, estimated maintenance and replacement costs, the number of operators required, and potential downtime losses due to malfunctions.

A more expensive but more stable, energy-efficient, and automated system is often more economical in the long run.

Visit operational case studies.

Don’t just look at the “sample projects” provided by the supplier; randomly or specifically visit projects that process similar materials and have been operating for more than a year. Talk to the on-site operators to understand the actual failure rate of the equipment, maintenance challenges, and the supplier’s after-sales response speed.

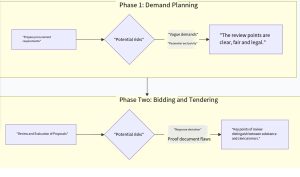

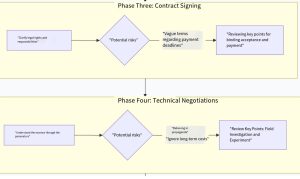

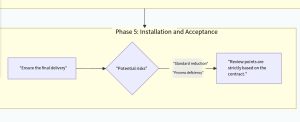

5. Risk Overview

To systematically mitigate risks, we have identified the key risk points throughout the entire waste sorting machine procurement process. The diagram below visually illustrates the five main stages from requirements planning to final acceptance, along with the core pitfalls to watch out for and key points for response and review at each stage.

This diagram clearly shows that risk is present throughout, and rigorous review points at each stage are the only “guide to avoiding pitfalls.”

For example, in the technical negotiation stage, the key is not to blindly believe advertising claims; verification must be conducted through on-site inspections and material experiments. In the final installation and acceptance stage, everything must be strictly implemented according to the contract terms, and standards cannot be lowered.

When a brand-new waste sorting machine roars into operation in the factory, its value depends not only on the thickness of the steel and the software algorithm, but also on a clear performance indicator definition in the procurement documents months ago, a rigorous test of real materials during technical negotiations, and a clear agreement in the contract regarding after-sales response time.